Exothermic Weldings – AmiableWeld®

Learn how Exothermic Welding is done in below Video:

Exothermic Weldings is also known as exothermic bonding, Thermite Welding, and Thermit Welding. There are many advantages of using Exothermic Weldings. The most important one is that the process produces a molecular joint and not just a mechanical one in between the conductors. It is produced through a starting reactant which provides enough energy to activate the Welding reaction. This takes place quickly and safely inside a graphite mold.

An Exothermic welding has higher mechanical strength than other forms of welding and excellent corrosion resistance. It is also highly stable when subject to repeated short-circuit pulses, and does not suffer from increased electrical resistance over the lifetime of the installation. However, the process is costly relative to another welding process, requires a supply of replaceable Graphite molds, suffers from a lack of repeatability, and can be impeded by wet conditions or bad weather (when performed outdoors).

Exothermic welding is a simple, cost-effective and permanent welded connection that uses a high-temperature exothermic reaction to create a molecular bond. It does not require an external heat or power source. Exothermic welding is the universally preferred method for making permanent copper-to-copper and copper-to-steel electrical connections. Its performance is superior to all existing surface-to-surface mechanical connectors. Exothermic welding works when others won’t!.

Exothermic welding is usually used for Exothermic Welding copper conductors but is suitable for Exothermic welding a wide range of metals, including stainless steel, cast iron, common steel, brass, bronze, and Monel. It is especially useful for joining dissimilar metals. The process is marketed under a variety of names such as AmiableWeld®.

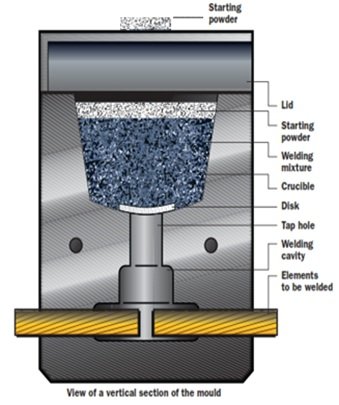

Exothermic welding is a simple, efficient, high-quality metal connection method, Exothermic welding by aluminothermic reaction generated by high temperature to make completely molten metal, in order to achieve high-quality welding effect. This reaction is conducted in the graphite mold of high-temperature resistance, exothermic reaction process takes only a few seconds.

Exothermic welding is a simple, efficient, high-quality metal connection method, Exothermic welding by aluminothermic reaction generated by high temperature to make completely molten metal, in order to achieve high-quality welding effect. This reaction is conducted in the graphite mold of high-temperature resistance, exothermic reaction process takes only a few seconds.

The mold is designed specifically for a certain union depending on the elements to be Welding and the joint type required. We guarantee all types of joints, not only copper cable unions but also to Welding tapes, brass metallic pieces, stainless steel, steel ground rods covered with copper, etc. It is especially useful for joining dissimilar metals.

Exothermic Welding Process:

The process of Exothermic Welding is a method of making electrical connections of copper to copper or copper to steel in which no outside source of heat or power is required. In this process, a special Welding material is placed into a high-temperature resistant mold and ignited.

Exothermic Welding Process

Exothermic Welding Live Demo

The process of igniting the particles creates extremely high heat and molten metal (exothermic reaction) up to 1400 degree Celsius and produces a molten metal slag. This liquid copper metal flows into the Welding cavity, filling any available space and completes the Welding.

The process of igniting the particles creates extremely high heat and molten metal (exothermic reaction) up to 1400 degree Celsius and produces a molten metal slag. This liquid copper metal flows into the Welding cavity, filling any available space and completes the Welding.

The Welding is then allowed to cool and solidify before it is removed from the mold. The mold is ready for the next Welding after a brief cleaning with a brush. This entire process takes only seconds to complete.

Exothermic Welding connections produce a permanent connection, superior in performance to any known mechanical or pressure type surface-to-surface contact connector. Because the connection produced is a molecular bond, an exothermic Welding connection will not loosen or increase in resistance over the lifetime of the installation.

The Exothermic Welding System is a welding process that utilizes an exothermic reaction to permanently join metal connections. Exothermic Welding uses a light-weight, clamp-on graphite mold to safely position and contains any weld required. The exothermic reaction creates an intense miniature furnace with temperatures exceeding 2,500 °F, instantly producing molten metal which flows into the weld cavity, filling any available space. After waiting adequate time after the initial process, the mold can be released and the finished connection removed.

Advantages of using Exothermic Welding:

- It guarantees the most common connections not only between copper cables but also for Welding tapes and metallic pieces made of brass, stainless steel, and copper coated steel earth rods. Current carrying (fusing) capacity equal to or greater than the conductor.

- It offers a permanent Welding and a low resistance connection, essential for achieving long wearing and trustworthy results in earthing.

- It does not corrode oxide or degrade with time and is resistant to galvanic coupling.

- It has higher mechanical and squeezing resistance than the conductors themselves.

- It has a superior electrical conductivity than the conductors themselves.

- The permanent molecular bond that will not loosen or corrode

- It is able to withstand repeated electrical discharges.

- No external power or heat required.

- Can be checked visually for quality

- It never increases its resistance.

- Will withstand repeated faults

- Will not deteriorate with age.

- No special skills required.

- Easily transportable

- Low labor costs